means the treatment wherein blood is removed from a donor, a platelet concentrate is divided, and also the remaining formed features are returned for the donor in addition to a part of the residual plasma. (g) Leukapheresis

In this Guide “manufacturing” is outlined to include all operations of receipt of supplies, output, packaging, repackaging, labeling, relabelling, excellent Handle, launch, storage, and distribution of APIs along with the related controls. In this particular Guide, the expression “should” signifies tips which are predicted to use Unless of course shown to generally be inapplicable or replaced by another shown to offer no less than an equal amount of excellent assurance.

A company's justification to the frequency of media fills in relation to shifts really should be danger dependent, depending upon the sort of operations and also the media fill analyze style. For closed

Evaluate possibility of contamination from factors, which include for the duration of ingredient manufacturing, storage, or due to the intrinsic hazard from source elements. Consider all doable sources of microbial contamination, including the pursuing:

Respective professionals needs to be obvious on job descriptions for each employee to stay away from misunderstandings and minimize the chance of challenges like overlapping responsibilities.

eight. Identify if corrective and preventive steps were being effective and verified or validated prior to implementation. Confirm that corrective and preventive steps never adversely have an effect on the completed unit.

is really a level of humidity very low adequate to circumvent the growth of undesirable microorganisms while in the completed item beneath the intended problems of manufacturing, storage, and distribution.

(2007) – which you'll access in its entirety on that backlink in case you’re truly seriously interested in this kind of thing. Which you have to be.

If you desire to to touch upon the current content material, please use the 'Content Feed-back' button underneath for Recommendations on speaking to the issuing agency

Even contemporary aseptic operations performed in closed RABS and isolators can working experience sterility and media fill failures, Regardless of the sizeable robustness of such systems about regular cleanroom and open RABS functions. The sterility examination is consequently A necessary aspect to monitor the state of control of an aseptic operation, and it's the final action in a very series of fundamental, necessary controls that collectively lead on the minimum amount assurance that a provided manufacturing operation manufactured a drug that meets its sterility claim. The sterility take a look at also shields people by potentially blocking the distribution of an aseptically processed drug product or service batch posing significant basic safety concerns that might not if not be quickly detected. All quality Management assessments, such as the sterility take a look at, have restrictions. Even though the sterility examination may not exhaustively evaluate batch sterility, the sterility test is, Nevertheless, a critical component of a comprehensive Command more info technique that may be meant to protect against microbiological contamination of drug solutions purporting to generally be sterile (21 CFR 211.113(b)). Innovations in sterility testing (e.g., quick microbiological solutions, genotyping) and the integration of these innovations into manufacturing operations might even further make improvements to prompt operational feedback, which can lead to considerable batch release efficiencies even though guaranteeing equal or improved capacity to detect nonsterility when compared While using the compendial process. FDA encourages using valuable testing improvements in conjunction with advanced manufacturing systems (e.g., robotic isolators) to reinforce approach layout and increase equally microbial detection and identification. References:

(viii) Records of manufacture which include distribution which allow them a complete background of the batch being traced are retained in a very comprehensible and obtainable form;

All manufacturing processes are Obviously described, systematically reviewed in the light of practical experience, and demonstrated being capable of consistently manufacturing medicinal merchandise of your required high quality and complying with their specs and/or marketing authorization;

The CGMP regulations for prescription drugs comprise minimal requirements for your procedures, facilities, and controls Utilized in manufacturing, processing, and packing of the drug products. The regulations Be sure that an item is Harmless for use, Which it has the components and toughness it promises to acquire.

Involving- and inside-locale variability can be a critical part of finished merchandise quality and for that reason should be evaluated. You should make reference to ASTM E2709 and ASTM E2810 for even further advice on developing check here acceptance criteria for the stratified sampling approach. References:

Edward Furlong Then & Now!

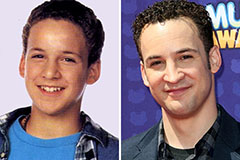

Edward Furlong Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!